Further development in the world of sweeper technology opened the gates to the future of efficient cleaning, but was far from the last word on the subject.

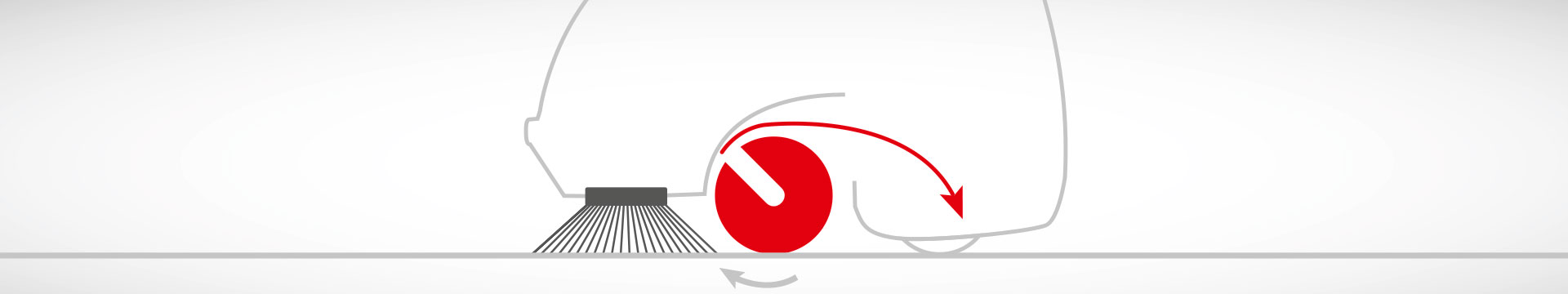

he numerous shortcomings of the dustpan principle made an improvement inevitable. Thus, the roller throw principle – especially for larger sweepers – was developed to compensate for these difficulties.